-

Auto parts testing product line

-

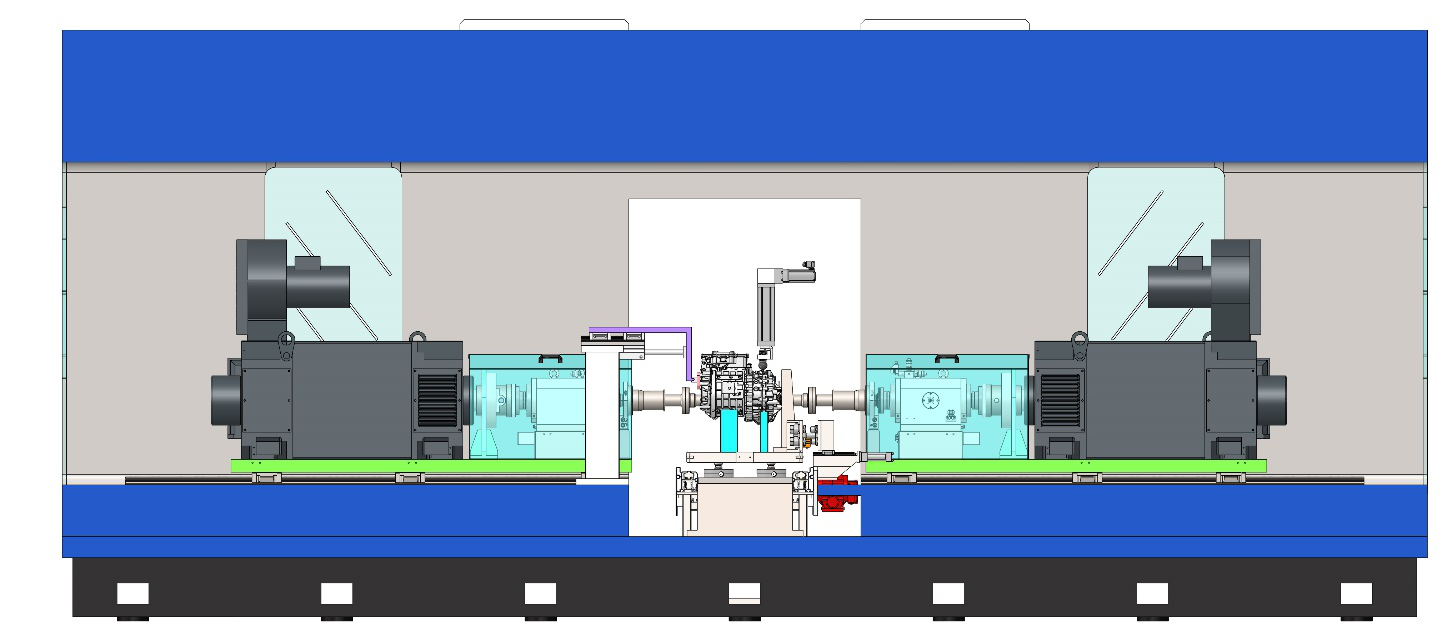

AT 4000--Dynamometer test system with integrated simulation vehicle model

-

AT 4000--NVH test system for electric drive assembly of new energy vehicles

-

AT 4000--towed test system for electric drive assembly of new energy vehicles

-

AT 4000--New Energy Vehicle Electric Drive Assembly Performance Test System

-

Robot component testing product line

-

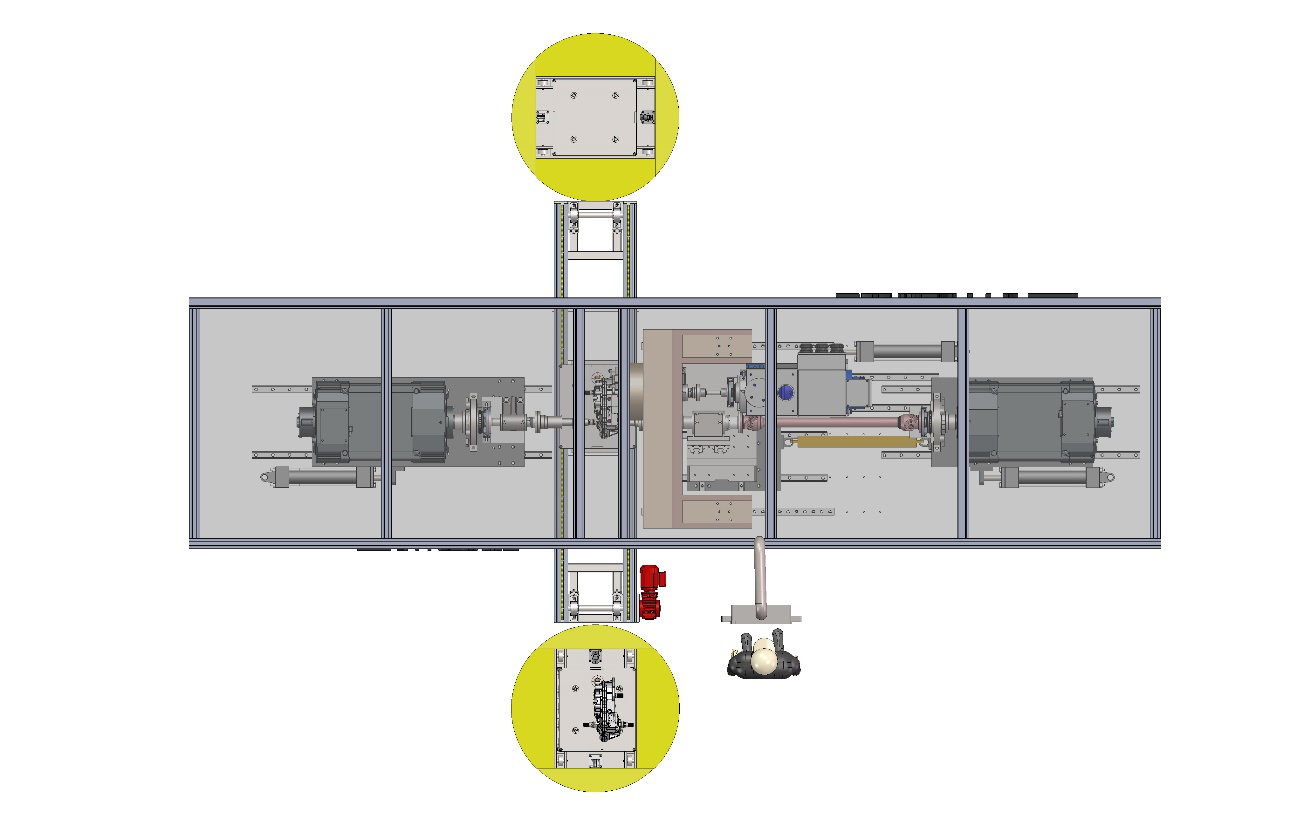

RT 4000--precision reducer (RV/harmonic/planetary) transmission error test system

-

RT 4000--precision reducer (RV/harmonic/planetary) fatigue life test system

-

RT 4000--precision reducer (RV/harmonic/planetary) bending stiffness system

-

RT 4000--precision reducer (RV/harmonic/planetary) performance comprehensive test system

-

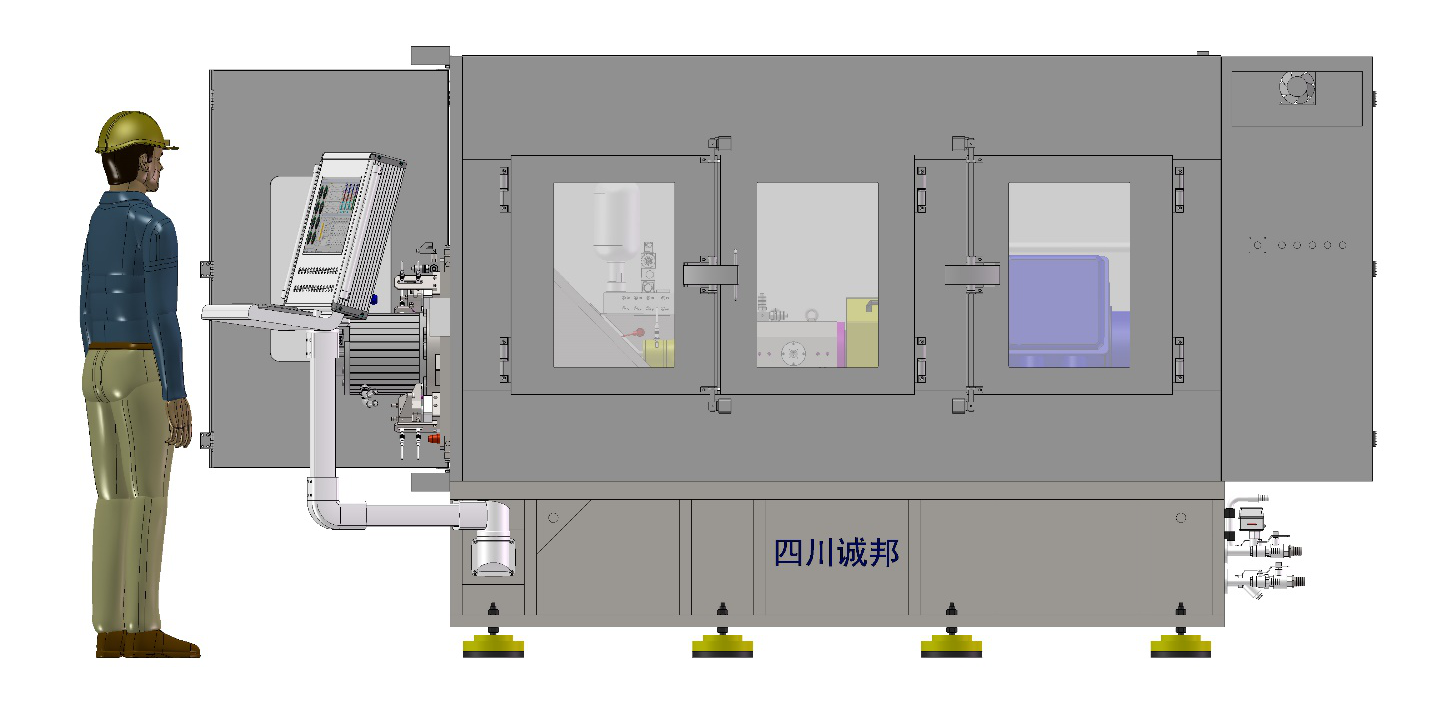

EOL4000 - EM motor online performance test system

The motor system of new energy automobile in the automobile industry must ensure that each motor passes the test before leaving the factory. The manufacturers have a growing demand for the test, so they can meet the EM motor production until the test leaves the factory. According to the output demand of each motor, the time and process of the whole production beat and detection beat, the production line is directly connected with the test. According to the National standard GB/T 18488.1-2015 "Part I Technical Conditions of Motors and Controllers for Electric Vehicles" GB/T 18488.2-2015 "Part II Test Methods for Motors and Controllers for Electric Vehicles" and referring to other national standards and various motor test standards, this system determines and tests the motor qualification of the motor online mode.

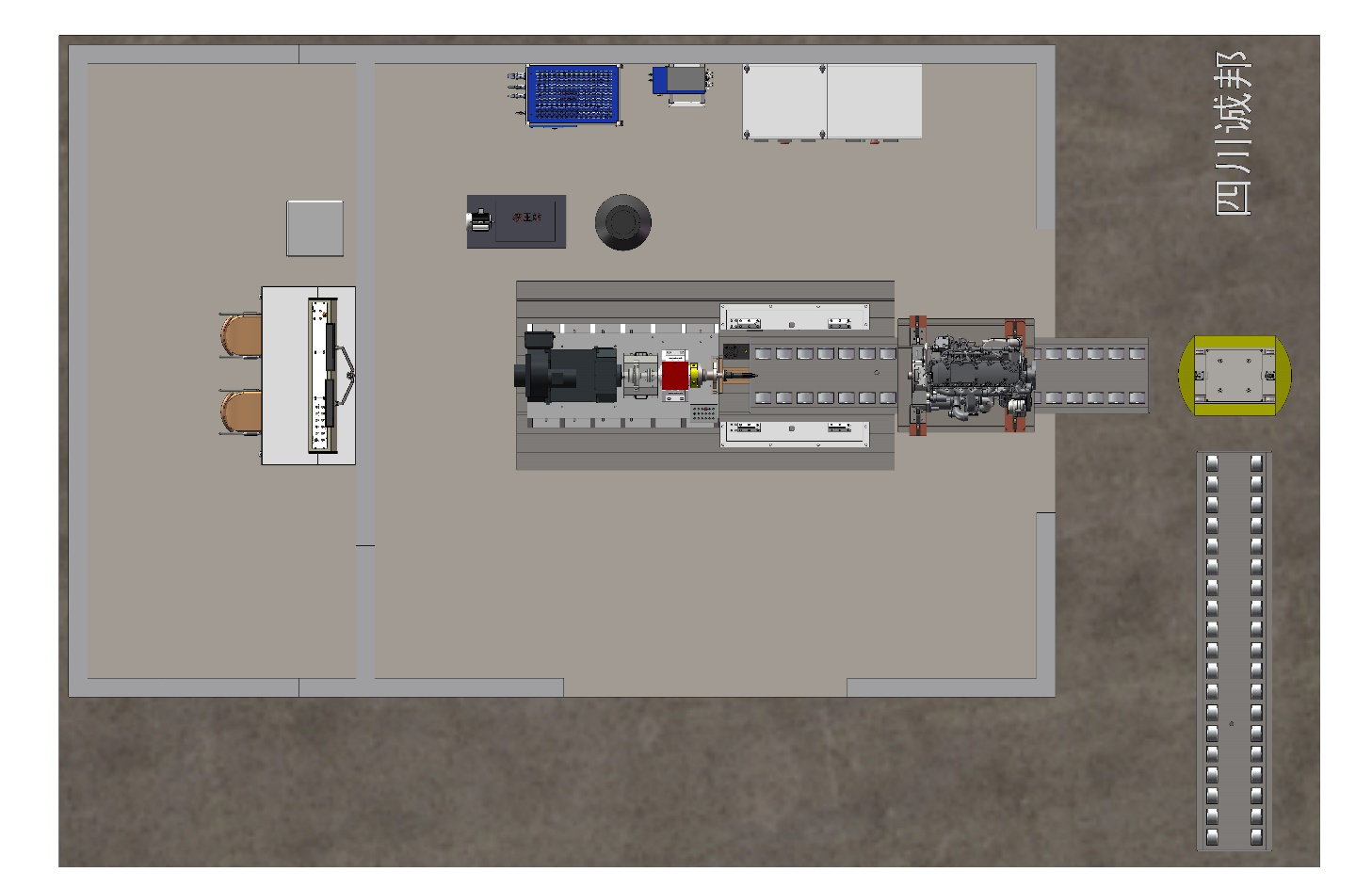

EOL4000 - EDS drive assembly on-line performance test system

The electric drive assembly system of new energy vehicles in the automotive industry must ensure that each vehicle passes the test and leaves the factory. Manufacturers have a growing demand for testing, and the EDS electric drive assembly production will be satisfied until the test leaves the factory. According to the output demand of each electric drive assembly, the time and process of the whole production beat and detection beat, the production line is directly connected with the test. EDS electric drive assembly must ensure the performance and quality of products (motor, controller and gearbox) in factory testing, so it is particularly important to strictly test the performance matching of the electric drive assembly of the whole vehicle system. According to the energy efficiency grade and test method of driving motor system and electric drive assembly for electric vehicles, and referring to other national standards and various assembly testing standards, the system determines and tests EDS assembly's factory qualification.

EOL4000 -- EV gearbox online test system

All EV systems of new energy vehicles must be tested to be qualified for delivery, and manufacturers have an increasing demand for testing. After EV system meets the requirements of delivery, EV system must be tested for delivery. According to the production demand of each pure electric reducer (EV), the time and process of the whole production beat and detection beat, the production line is directly connected with the test. Pure electric speed reducer (EV) must ensure the performance of gearbox and product quality in factory inspection, so it is very important to test and analyze the performance of the speed reducer strictly. According to the NATIONAL standard QC/T 1022-2015 "Technical Conditions of Reduction Gear Assembly for Pure Electric Passenger Vehicles" and referring to other national standards and various assembly testing standards, the test purpose of the pure electric reduction gear (EV) is to determine and test the factory qualification of the pure electric reduction gear (EV).

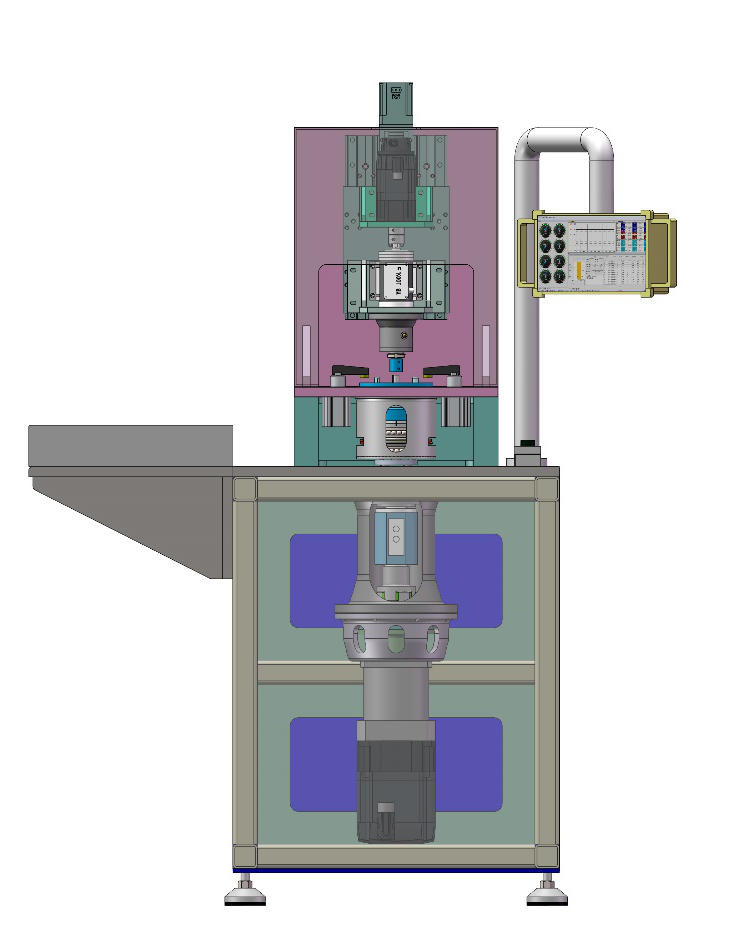

EOL4000 - Precision reducer (RV/ Harmonic/planet) factory on-line test system

At present, the competition of industrial robots has risen to the level of national industrial strategy, and its key components precision reducer manufacturing factory inspection. In order to ensure the high rigidity and positioning accuracy of industrial robots, RV reducer should have the characteristics of short transmission chain, small physical examination, large power and high accuracy, and high requirements for manufacturing and testing. At present, the precision reducer (RV/ harmonic/planet) manufacturer's production demand, the entire production beat and detection beat time and process, production line production completed direct docking with the test. Precision reducer (RV/ harmonic/planet) must ensure the performance and quality of reducer products in factory detection, so it is particularly important to strictly test and analyze the performance of reducer. The system is based on the GB/T 35089-2018 precision gear transmission test method for robots and the comprehensive performance test of each reducer according to the requirements of other national standards.

2255/5000 EOL4000 -- Engine Factory online Test System (DL/DW series)

At present, the competition in the automobile industry pays attention to the safety, comfort, environmental protection, power and energy saving of automobiles. Automobile engines directly or indirectly affect some major technical skills of automobiles, in order to ensure the performance and delivery quality of automobiles. At present, according to the whole production and testing process of the automobile factory, the production line has been directly connected with the test. The engine performance and product quality must be guaranteed during ex-factory testing. This system is based on the GB/T 18297-2001 automobile engine performance test method, GB/T 19055-2003 automobile engine reliability test method, and refers to other national standards and various engine ex-factory performance tests.